Transformers are an important component of any power system, and they need to be maintained properly to ensure their efficiency and longevity. One key aspect of transformer maintenance is drying them out. Moisture can cause many problems in transformers, including insulation breakdown, corrosion, and reduced dielectric strength. That’s where vacuum transformer drying ovens come in.

What is a Vacuum Transformer Drying Oven?

A vacuum transformer drying oven is a specialized piece of equipment used to remove moisture from transformers. It works by creating a vacuum inside the oven chamber, which lowers the boiling point of water. The transformer is heated while under vacuum, causing the moisture to evaporate and be removed from the system.

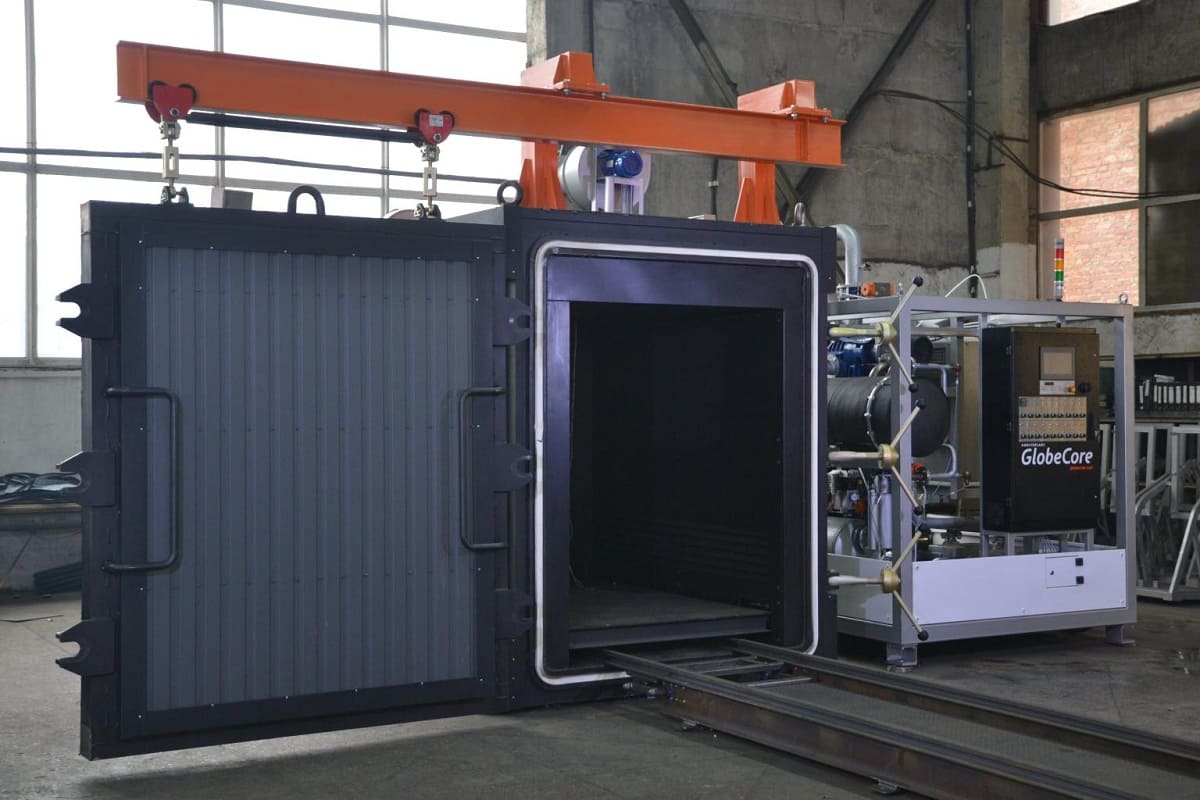

The oven typically consists of a chamber, heating elements, vacuum pump, and controls for temperature and pressure. Some models may also include a refrigeration unit or other cooling system to aid in the removal of moisture.

Why Use a Vacuum Transformer Drying Oven?

Drying out a transformer with a vacuum oven has several benefits over other methods. Firstly, it allows for a more thorough removal of moisture since the boiling point of water is lower under vacuum conditions. This means that even deeply embedded moisture can be removed without damaging the transformer.

Secondly, using a vacuum oven is a faster method of drying than other techniques, such as hot oil circulation. This means less downtime for the transformer and reduced labor costs.

Lastly, vacuum drying is also more environmentally friendly since it doesn’t produce waste material like hot oil systems do.

How Does Vacuum Transformer Drying Work?

Vacuum drying is a multi-step process that involves several phases:

Conditioning Phase:

Initially, the transformer is placed in the oven chamber while under atmospheric pressure. The internal temperature of the transformer gradually increases, causing moisture to vaporize.

Dehydration Phase:

Once the transformer reaches a specific temperature, the vacuum pump turns on and reduces the pressure inside the chamber. This causes the boiling point of water to lower, which further assists in moisture removal.

Cooling Phase:

After the dehydration phase is complete, the oven chamber is slowly refilled with air while cooling the transformer. This helps prevent any moisture from being re-introduced to the system.

Best 5 Vacuum Transformer Drying Oven Manufacturers

When it comes to transformer maintenance, a vacuum transformer drying oven is an essential piece of equipment. However, choosing the right manufacturer is just as important as selecting the right equipment. Here are five of the best vacuum transformer drying oven manufacturers on the market today.

1, Lexusvacuum

Website: https://www.lexusvacuum.com/

Since 2018, Lexus vacuum has been a top-level professional trader and exporter of vacuum equipment. With years of experience and resources, they have built a strong reputation in this field, earning the trust of thousands of clients at home and abroad. In addition to the machine, they offer solutions and services as well.

Lexus vacuum has been providing types of high standard products and service to their customers around the world.In the past 10 years, they have researched various kinds of vacuum drying oven, vacuum impregnation, vacuum casting, metal melting furnace,Metal casting Equipment & Heat treatment Oven.

The Lexus vacuum team consists of talented, experienced engineers who have worked in the vacuum equipment manufacturing industry for many years.

The Lexus vacuum company will continue to provide metal melting and heating solutions throughout the world through its extensive network of global locations, partnerships, and agents in America, Europe, and Asia.

2, Hering-vpt

Website: https://www.hering-vpt.com/

HERING built its first oil purification plant in 1909 – making it possible to treat insulating oil internally and externally with vapour-oil boilers. Several vacuum products, mainly for the transformer industry, were invented as a result of this, including Transformer Drying ovens, Impregnating Plants and other vacuum products. The experience they have gained over the past 100 years has enabled them to continuously improve their plants’ efficiency through innovation. HERING VPT developed strong client relationships with a large number of important manufacturers, notably electrical, chemical, and other industries, based on its extensive experience.

3, Globecore

Website: https://globecore.com/

GlobeCore is a leading manufacturer and supplier of industrial equipment for the production of bitumen emulsions, modified bitumen, oil regeneration and oil purification, fuel blending, biodiesel production, wet milling and nonoblending.

4, Nachengg

Website: https://nachengg.net/

Founded in 2008, NACH ENGINEERING PVT. LTD. manufactures transformer oil filters and vacuum pressure impregnation systems for the transformer and motor-generator industry. Its products are also exported to countries in Africa, South America, Asia Pacific, UAE and the Middle East.

They are registered vendors for different Government of India Public Sector Undertakings in the power sector, Indian Railway Subsidiaries, multinational companies like Siemens, ABB, and CGL.

In order to achieve cutting-edge technology in all of its products, NACH maintains design, research, and development as continuous ongoing activities. Employees at NACH are motivated and self-driven to ensure customer satisfaction and quality products that tend to give zero breakdowns of equipment.

5, Transformer-laminations

Website: https://www.transformer-laminations.com/

The Cangzhou Kenuo International Co., Ltd. has been operating for more than two decades. As one of the leading Exporters, Manufacturers, Suppliers of Transformer Spare Parts, Transformer Components, Oil Level Indicators, Transformer Lamination Cutting Machines, Electrical Steel Cutting Equipment, Silicon Steel Cutting Machinery, etc., they have carved a niche in the industry. As per the requirements of our clients, they offer these in various power capacities, designs, sizes and dimensions.

The products they offer are highly regarded for their ease of installation, low power consumption, durability, and impeccable designs. Across the national and international market, all of their products are praised for their attractive attributes. In addition, the reasonable prices and prompt deliveries ensure long term client retention for future business.