These are also called machine vision systems. With such systems, you can perform image based inspections for industrial and manufacturing applications. They are basically automated systems. 2D & 3D systems are mostly used for automated sorting, inspections, robot guidance and quality control. To know the details, check out reputed sites like https://www.sipotek.net/!!

Custom Design Visual Inspection Systems & its uses

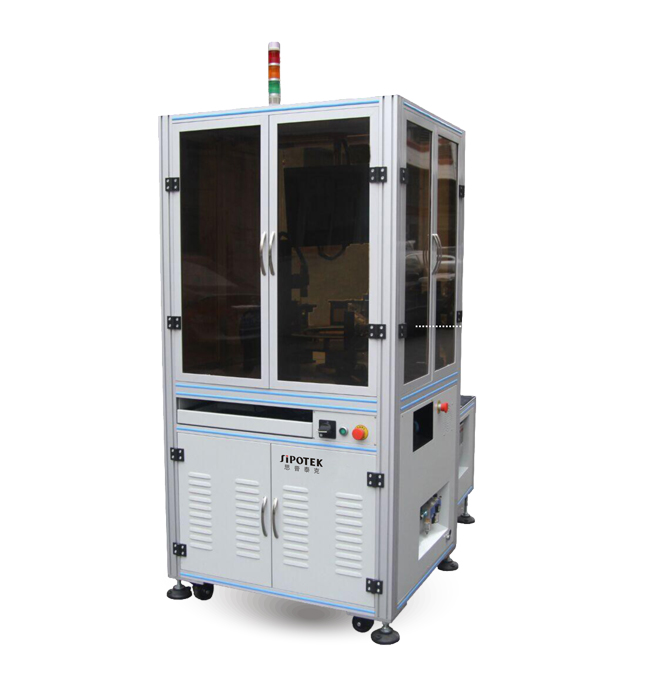

These machines similar to other inspection machine features 1+ cameras. Few even are provided with video and lighting. It measures parts and also verifies their position. Besides this, it is powerful and recognizes easily part shape. High speed sorting is one beneficial aspect to enjoy using this machine. This equipment is quite intelligent and can take crucial decisions, which is likely to impact the whole process. Installation of these systems in the lines does offer continuous useful information.

System application

Custom Design Visual Inspection Systems are found suitable for diverse fields. They are quite ideal for packing or production center especially in those where quality control is paramount. Robotic devices for example, may use this to derive pat positions to automate and streamline the manufacturing procedure. Vision systems also help to collect data, thereby increasing line efficiency. It also helps to sort, pack and provide assistance with wide range of applications.

System received information can help identify problems in lines to improve efficiency. It also helps prevent those systems not meeting set efficiency standards. They identify products not meeting quality standards.

Industries using such machines for inspection purpose

As modern technology is used by these devices, it is possible to customize designs to meet the requirements of many industries. Companies use this technology to inspect their parts and products. Few even use it for security purpose.

Visual inspection machines like electronics, consumer goods life sciences, medical imaging, drinks, semiconductors, foods, drinks, packing & medicine, automotive, etc. are used in many industries.

Benefits derived

It includes better uptime, enhanced product and reduced expenses. Using this system, companies are able to carry out 100% precise inspection and improve quality control and meet given specifications.

Basic components

With each application being different, there are used specific components, which are given below.

•

Cameras & Optics:

This inspection machine uses one or more cameras and optics to photograph the to-be inspected components. This could be a digital or analog camera. Besides this, cameras could be progressive scan, line scan, RGB color, variable scan, monochrome or composite color. Camera selection is likely to be based upon needs of the application.

•

Lighting:

Even without sufficient light cameras do take excellent photos. Bright light is essential for optimal component illumination to be photographed. There are used different lighting types in these machines like fluorescent, LED, incandescent and fiber optic, etc.

•

Computer Processor:

The CPU or computer processor as the name suggests is a PC or digital signal processor. Ruggedized computers are typically used as there is plenty of dirt, vibration and high temperature in the manufacturing environment.

•

Presence Sensor:

This device sends out alerts to machines to notify that there are ahead components to-be inspected. Once the target position is reached by the component, the machine takes an image of the same.

•

Frame Grabber:

Its role is to interface CPU with the machine camera. Digital or analog image is converted in data interview format which is better understood by the computer. The frame grabber usually is present in varying configurations to help support wide range of camera and CPU types.

•

Digital I/O:

It is also called network actions, where inspection results are sent to system, which manages the entire manufacturing process it is performed once component inspection is completed. The process usually uses network card. Also is used an interface board alternatively.

•

Machine vision program:

There are used different software programs for controlling this machine. Software program’s main purpose is creation and execution of image data as well as to perform acquired infection.

Conclusion

It is important to understand that not all manufacturing processes that are carried out globally are found to be the same. Hence, you need to take out some precious time and try to find out your specific machine requirements and components. The right component type is one that will be based on your specific operational needs. To derive accurate results, it is crucial on your part to take the correct decision to invest in one. Ideally, it will be wise to consult a knowledgeable and experienced machine expert who can provide you with valuable information in details. This way, you can come up with an informed decision that will prove to be more than beneficial for your business.

Interested manufacturers who are eager to enhance their overall production process can avail custom options with regards to visual inspection systems to match perfectly their business requirements. This will help increase efficiency