Aipcba are experts and can even manage complex design issues like polarity marks omission. The latter causes significant delays in the project that can now be eliminated. Concerning the electronics world, quality is of the paramount importance. Better quality products will only mean higher prices. At this point of time, there have emerged several PCB manufacturers in the market. Hence first-time shoppers are likely to find it tough to find the best one among the lot to meet their specific business needs. The well-established companies can help reduce costs involved in PCB assembling units without sacrificing on the quality aspect.

Factors to consider

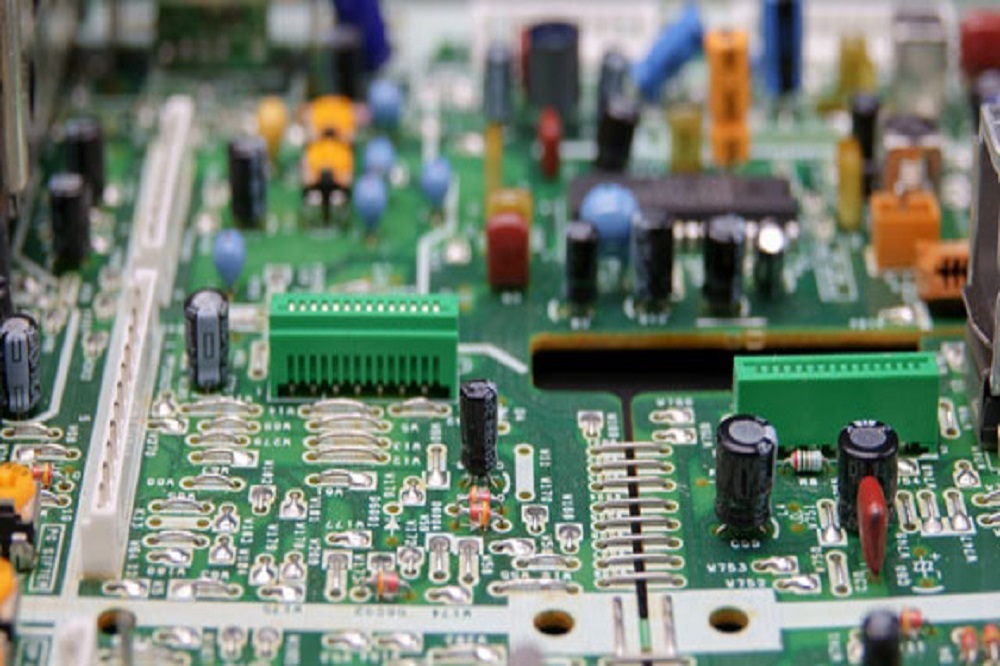

You can find pcb assembly units being used in different products, ranging from complex, high performance servers to simple and complex electronic goods. When concerning identifying reputed PCB suppliers, you need to take into consideration several aspects. At every assembly and production stage, the reputed companies tend to run a thorough check. This is to identify if the designs are in proper sync with the client laid specifications.

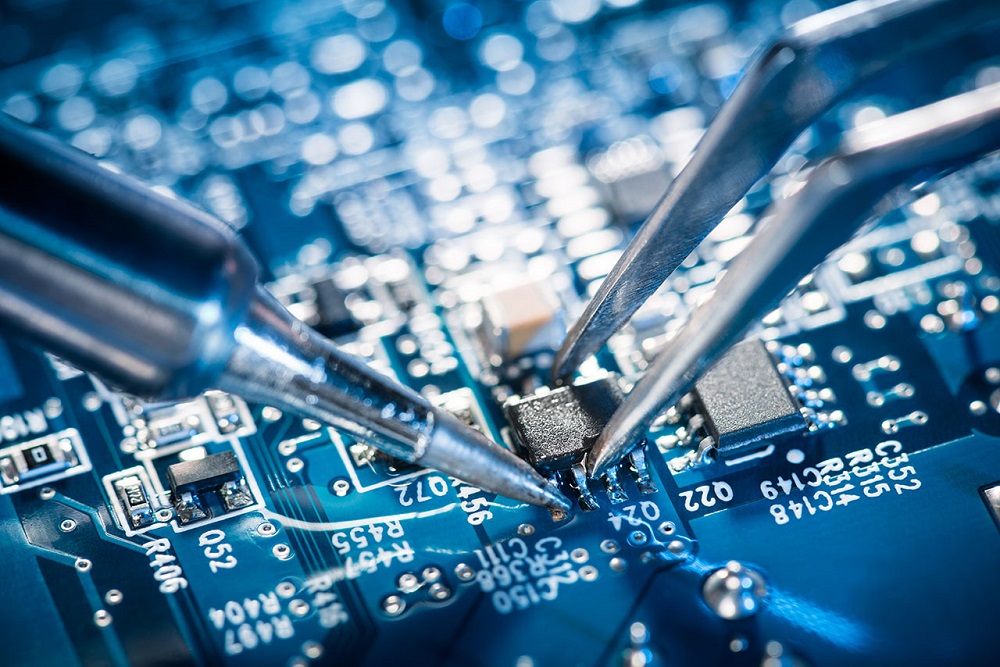

Managing flaws

There are bound to be issues taking up place especially while shopping. Quality is one such aspect that shoppers might compromise for price, either knowingly or unknowingly. The well-established PCB manufacturing companies like https://www.aipcba.com/ do take into account different factors. It includes high density design, communication lines, conductivity and durability. They also carry out stringent inspection of the manufactured products to make sure that no inherent flaws are noticed in it. Tests are carried out via a substantial metric to judge quality of the product manufactured. It is essential to check periodically the PCB to ensure it meets the stringent quality measures as laid down and demanded by the clients.

Quality certifications

The pcba manufacturing company is likely to comply strictly with the prevailing industry standards as set by the international and national organizations. They also use only top rated flame retardant hoses to enable self extinguishing and fire resistance purposes. The highly responsible and competent manufacturer ensures furnishing of conformance certificates with every shipment made.

Industrial experience

A major factor that results in demarcation line between PCB manufacturers and the counterparts is their industrial experience. The experienced manufacturer is likely to enjoy higher adaptability to using modern technology and sophisticated devices for their production purpose. It is necessary to ensure that the selected pcba manufacturer should have sufficient experience in dealing with clients having similar demands.

Pricing structure

Pcb assembly pricing structure tends to differ with quality and design. If change exists in base material or solders mask material, then PCB cost is likely to be witness significant impact. Hence, before buying, it is essential to ensure proper balance being present between quality and price.

Customer support

If things do not go as planned, then personal touch will be essential. Quality customer support is of prime importance. Progressive companies tend to have realized the potential benefits of value-based customer centric services. The efficient pcba manufacturer is one who will be ready to join technical discussions.

Getting hold of a reputed turnkey pcb assembly manufacturer will enable quality results.